The primary and secondary uses of these folding boxes are simple. The materials used to make these boxes, such as cardboard and corrugated cardboard, are also simple. However, there are different types of folded cardboard boxes - straight folded ends, reverse folded ends, snap lock bottoms, and sealed ends, to name a few.

Straight Tuck End

The straight folded end style is the most common type of folding box. Almost all products require this type of packaging, especially since the front display panel is a large clear window front to identify the product inside. The top and bottom of the case "folds" from the front part to the back of the box, preventing any raw edges from being exposed.

Reverse Tuck End

Reverse folding ends are the type of folding box that is very similar to the straight folding ends of a paddock. The only difference is that the top shell of a folding cardboard box covers or "plugs" from the back part to the front of the box, while the bottom shell seals or "plugs" from the front part to the back of the box. This type of folding box is usually used in cases where the front display panel is opaque and does not open to expose the product inside. Cosmetics are the most common type of product to use this type of packaging.

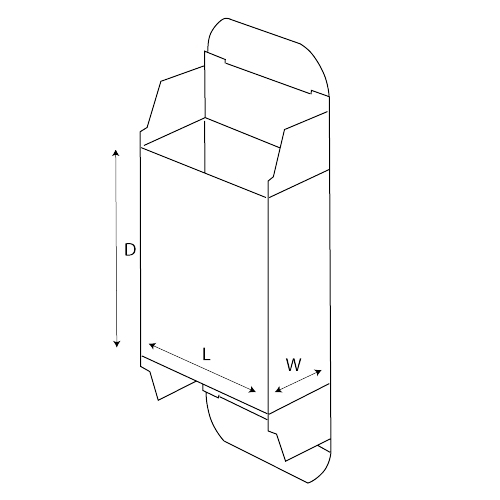

Snap Lock Bottom

Now, snap-lock bottoms are the type of folding box, unlike the straight-fold end and reverse-fold end types, but this is still a common type of packaging. Unlike the straight and reverse fold end types, which can be formed and closed by the machine, the snap lock bottom type is locked and closed by hand.

The bottom housing has different sized locking panels. The larger piece should go first, followed by the two dust covers and the smaller piece that finally seals the bottom of the folded box. Snap-lock bottoms are typically used for cosmetics, pharmaceutical and medical products, and other retail products that are heavier and require extra security.

Next: Custom Printing Of Metallic Inks

Previous: The Importance Of Paper Bags