It means that each color printed on the paper is a combination of four colors from the printing process - cyan, magenta, yellow and black.

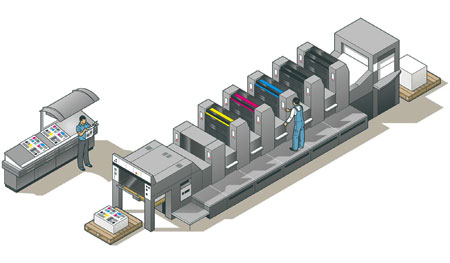

Start-to-finish printing process using offset printing

This is a brief overview of the various steps in the production process and their respective contributions. Click on one of the areas below to learn more about their specific functions and technologies.

The Design Phase

During the design phase, the designer completes the following tasks.

○ The overall look and feel of the work

○ Typography

○ Graphic creation

○ Page layout

The following tasks can be done by the designer or the pre-press department of the printer

○ Color Induction

○ Creating the print sheet

○ Scanning halftones and line art

The Prepress Stage

In the pre-press phase, the artwork is taken from its delivered state (either as reflected art or as a digital file) all the way to the printing plate.

The specific process is as follows. First, the artwork is transferred to a negative, which is imaged by an image processor for digital files, or a photocopier for reflective artwork. Second, the pages are stripped to a flat surface to reflect the way the pages are printed on the printing plate. Third, this flat surface is burned onto a metal plate that will be wrapped around the printing cylinder.

Each color usually has its own film and plane. The exception is when few colors are used and the colors used do not touch each other's colors at any time. In this case, the color will simply be masked during the firing of the first plate and then exposed during the firing of the next plate.

The following procedures are performed by an electronic prepress operator or deinker.

○ Image Setup

○ Shoot camera ready art and halftones

○ Scanning halftones and line art

○ Color trapping

○ Imposition of plates

○ Film stripping

○ Plate making

The Printing Stage

The printing stage consists of transferring the image to paper. Offset lithography is based on two main principles.

Water and grease cannot be mixed.

The ink is offset from the printing plate (positive image) to the blanket (negative image) and then to the substrate (which becomes

positive again).

positive again).When a plate is made, the printed image is given an oil and water resistance, while the non-printed areas are given a water and ink resistance. On a printing press, the plate is mounted on a plate cylinder and, as it rotates, comes into contact with a cylinder impregnated with water (or wetting solution) and a cylinder impregnated with ink. The dampening solution wets the non-printing areas and prevents the ink from penetrating into these areas. The ink wets the image areas and these areas are transferred to the intermediate blanket roller. The paper captures the image as it passes between the blanket cylinder and the impression cylinder.

While this process primarily involves one machine, there are many areas that require attention.

To ensure high-quality printing, the printer must:

○ Match the specified ink color

○ Control dot gain

○ Minimize paper movement

○ Minimize image distortion or noise, such as dust and kiss marks

○ Check that pages are correct for each other

○ Evaluate halftone quality, trying to maintain highlight and shadow detail

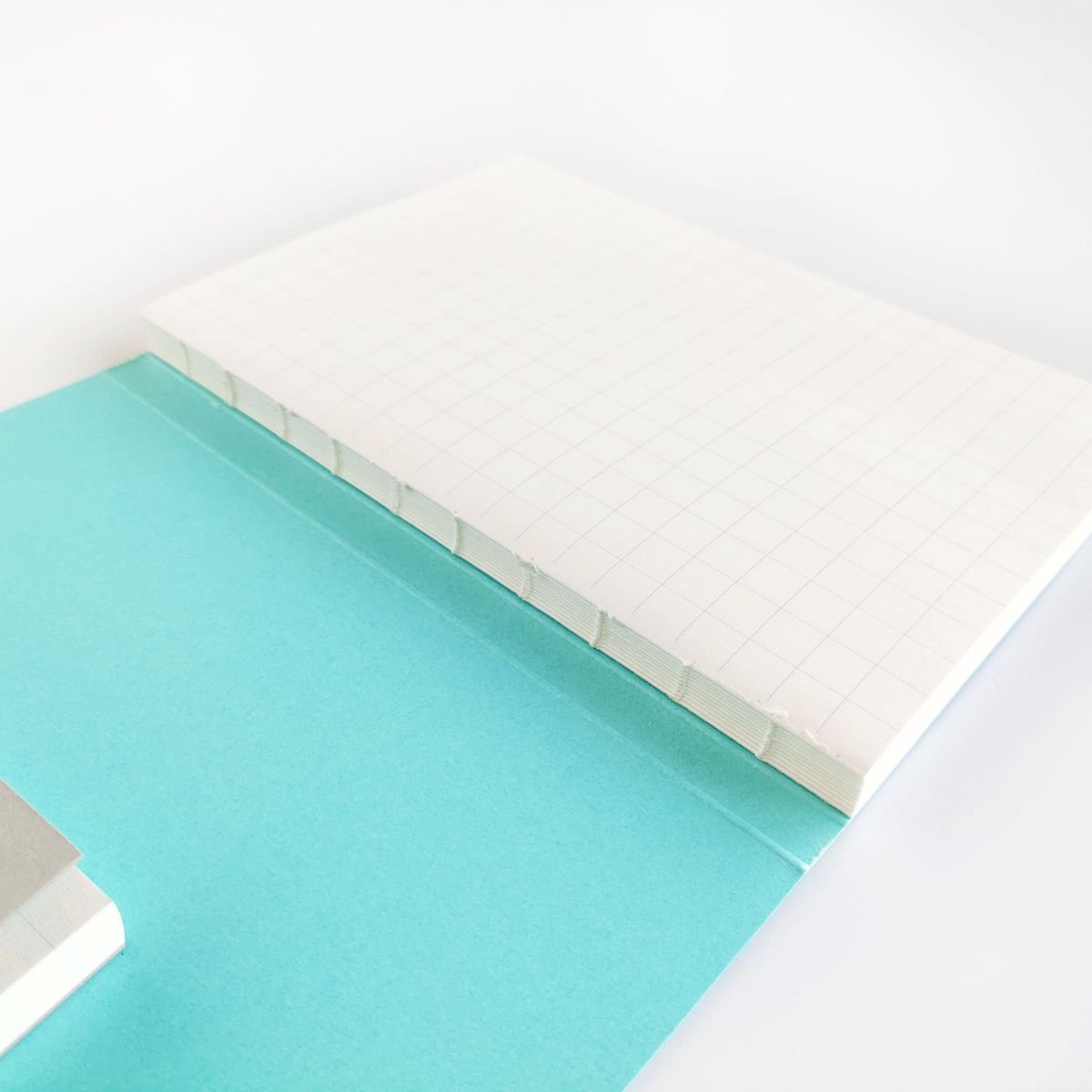

The Bindery Stage

The Bindery Stage is where any trimming, folding, punching, finishing, sewing or gluing is done as needed.

Inkworks trims and folds in-house and works closely with an outside bindery to finish, stitch and glue.

Next: Types Of Printing

Previous: Four Color Process And How It Works